A widely used source for energy, LPG is known for both its efficiency and versatility. Renowned due to its precise temperature control, LPG supplies heat evenly and immediately for all industrial and household purposes better than petrol or any other fuel oil. However, despite being an unadulterated fuel that has no scope for spilling, contamination […]

Will it be a shocker if we told you that the fuel that powers household kitchens is now likely to power large water vessels? Well, that’s the possible future. Liquified Petroleum Gas or LPG is emerging as the best alternative fuel for several industries including marine. But why do we need an alternative fuel for […]

The Healthcare sector is just like any other commercial sector, where hospitals and the pharmaceutical industry use LPG gas for a range of applications. High calorific value and ease of installation are some of the several benefits of LPG gas that make it the right choice for rigorous application. One can procure LPG gas from […]

In the era of technological breakthroughs and the increase in industries, the looming environmental concerns precipitated the choice of fuel. Today, LPG is emerging as an alternative industrial fuel and its range of advantages ensures the selection is apt for industries. Private LPG gas agency is fueling the application of LPG in industries, due to […]

Since the liberalization and deregulation of the Indian economy in 1991, industries are exempt from obtaining an industrial license to start manufacturing in India. The growth of industries in India has led to a revolution in the economy and made-in-India products. To overcome the growing pollution through industries, the government has advised them to use […]

To fuel large steam boilers in industries, it is important to have high heat generating fuel. LPG Gas is the right choice for manufacturing industries to fuel the need for running the steam boilers without stoppage. Steam is an integral part of manufacturing and process industries all over the world. In the manufacturing sector, steam […]

LPG is gaining attraction in the industrial sector due to its many benefits. One of the reasons is clean burning and high calorific value. In industry, no one can afford stoppage of productivity due to lack of fuel, which is why it is important to choose the appropriate LPG gas agency. For the supply of […]

Biscuit baking is an industry that depends completely on LPG for the manufacturing process. So, if you are in the biscuit industry, this blog is an apt read for you! Life before biscuit was without crunch, it is the delicacy that people of every age group love! The process that is involved in biscuit manufacturing […]

The handloom and textile industries of India are around 5000 years old! But the methods have changed a lot from olden times, and one of them is the adaptability of LPG gas. The LPG gas company in India plays a vital role in improving the working condition and efficiency of the handloom industry. The domestic […]

Before opening a hotel or restaurant one always searches for an LPG gas agency or ‘private LPG gas agency near me’. Hotel or Restaurants solely depends on the hospitability of consumers by providing quick customized services. Yes, we agree there are other factors too such as aesthetics, quality service, and operational efficiency, but if the […]

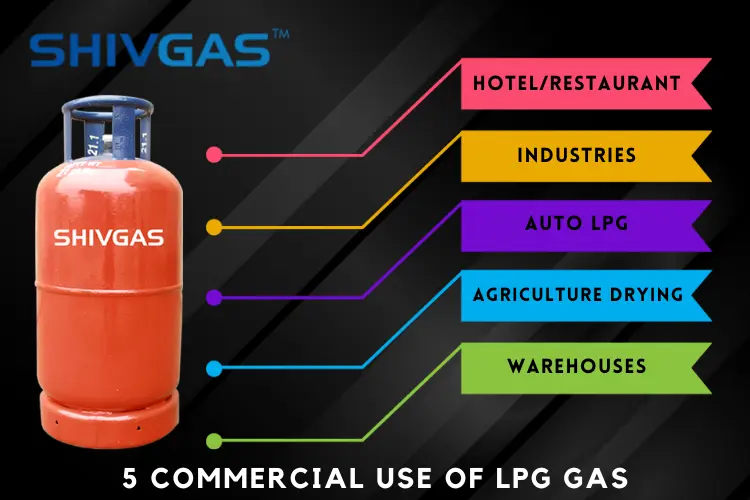

There are multiple uses of LPG gas in the industrial sector. It is a clean fuel with a high calorific value and is, therefore, one of the most versatile energy sources. Industrial LPG plays a significant role in many industrial applications, such as powering ovens, furnaces, and heating tools. Besides being a ubiquitous part of […]

Are you confused between LPG gas and Natural gas, which one is better? With the increase in the demand for cleaner fuel, LPG and natural gas have become two reliable alternatives to traditional cooking fuels. However, natural gas and LPG are chemically different gases. LPG is the acronym for liquefied petroleum gas, the chemical formula […]

LPG stands for Liquified Petroleum Gas. It has numerous industrial as well as domestic use. Being a cleaner fuel, it does not cause much damage to the environment like traditional fuels. Why LPG is a Good Option for Commercial Use? Efficiency LPG has a high calorific value, compared to traditional fuels. It does not take […]