Summary: The expiry date of an LPG cylinder, also called the resetting date or due date, is printed on the metal stay of the cylinder in the format A/B/C/D–YY, where the letter indicates the quarter (A = Jan–Mar, B = Apr–Jun, C = Jul–Sep and D = Oct–Dec) and YY is the year. For example, A-28 means the cylinder is due for mandatory testing between January and March 2028; after this date, it should not be used until revalidated for safety.

During delivery, we check the weight but never the expiry date of gas cylinders. As a matter of fact, many people are still unaware that LPG cylinders have an expiry date, also known as a resetting date. Checking the gas cylinder expiry date is essential for safety. Experts advise stopping using the cylinder once this date has been crossed. Well, the technical term, as the LPG gas companies in India say, LPG cylinders do not have a fixed expiry date, it is the Resetting Date or Testing Due Date, which many consumers call the expiry date. If you’re unsure how to check the gas cylinder expiry date, this blog will guide you in detail.

LPG Cylinders are made of composite material and steel. According to the standards approved by the Chief Controller of Explosives (CCOE), the cylinders should be made of special steel with a protective coating.

The manufacturing of the LPG gas cylinders includes raw materials like carbon fiber and reinforced polymer. These materials make the cylinder lighter in weight and enhance its tensile strength.

The reinforced cylinder contains carbon fiber as per the PESO circular No. R.4(2) 100/2007 dated 20.08.2007. All the cylinders are required to be taken to the first statutory testing and painting after 10 years, and it must be followed by every 5 years.

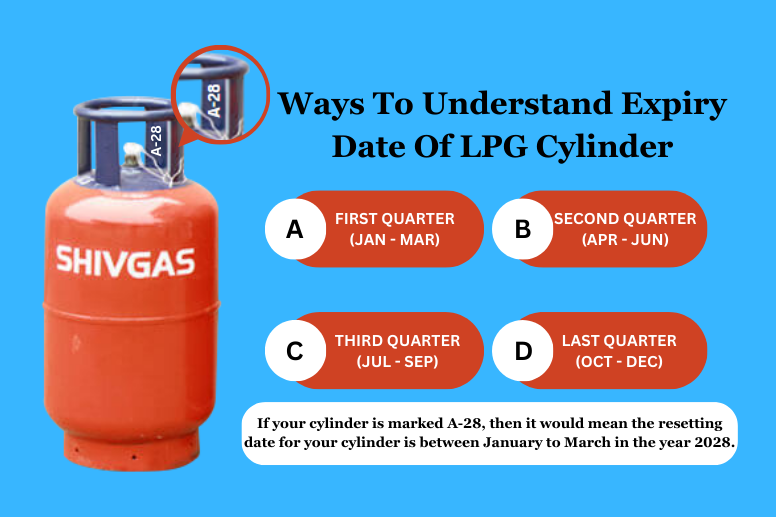

To locate the LPG gas cylinder expiry date, look at the side of the cylinder’s vertical stay. The date is written in the form of the alphabet A, B, C, or D followed by 2 digits (example: A-28). Here’s what each letter means:

The two digits indicate the year (YY) till it is valid. For example, A-28 would mean the cylinder is due for testing in the first quarter of 2028. So, for instance, if your cylinder is marked A-28, the gas cylinder expiry date is between January to March of the year 2028.

While collecting the cylinder from the distributor, always check the LPG cylinder expiry date to ensure its safety precautions. You can also ask your delivery person to check the due date on the cylinder.

Cylinders that have passed the gas cylinder expiry date are transported to the bottling center. The LPG gas cylinder is tested in the bottling center to check its durability. Some of the common tests that are performed on the cylinder for quality checking are hydrostatic tests, burst tests, ultimate tensile strength tests, impact tests, and pressure cycling tests.

Once the tests are done, the LPG companies mark the cylinders’ resetting date on the bottling center where these cylinders are segregated.

Also Read: How To Tackle The Issue Of Household LPG Cylinder Sweating

For cylinders that are past their gas cylinder expiry date, proper care is taken by distributors to ensure these bottles do not end up in the market. The norms and standards set by the government are followed while refilling the cylinders. Each cylinder is visually tested for defects, and then Statutory Testing and painting are done.

Also Read: Ways To Prevent LPG Gas Explosion At Home

An LPG cylinder has a lifespan of 10 to 30 years, and in between this time, it is mandatory to be checked twice. In the hydro test, the cylinder is filled with water for testing, and in the pneumatic test 5 times, the pressure at which LPG is stored is applied to test the quality of the cylinder. If the cylinders fail in any, they are discarded to be filled again, and this ends up a scrape.

Most LPG gas companies in India, like SHIVGAS, adhere to the norms of gas cylinder expiry dates. With due diligence, they ensure that no cylinder cycles back to the market without proper segregation.

SHIVGAS believes in taking all steps necessary to make the life of a consumer easier. Starting from auto-ordering technology to on-time delivery on the doorstep, we are always there to support your cooking needs.

Checking the gas cylinder expiry date is crucial for safety reasons. An expired cylinder may not be safe to use and could pose risks of leakage or other hazards.

If you discover that your LPG cylinder is expired, you should immediately contact your LPG supplier for a replacement. Please do not use the cylinder until it has been replaced.

No, even if an expired cylinder appears to be in good condition, it should not be used. The structural integrity of the cylinder could be compromised, posing serious safety risks.

Besides the gas cylinder expiry date, you should also check for the cylinder’s tare weight (empty weight) and the maximum allowable fill weight. This ensures the cylinder is not overfilled, which can be dangerous.

It’s a good practice to check the gas cylinder expiry date every time you receive a new cylinder from your supplier. This ensures you are always using a safe and compliant cylinder.

It is recommended that you exchange an expired cylinder with your original supplier to ensure proper handling and compliance with safety regulations.

Comment (0)