When you turn on your gas stove and notice that steady blue flame, it’s a reassuring sign that your kitchen is ready for a new day. The invisible force behind that flame is liquefied petroleum gas (LPG). It is a fuel that quietly powers our everyday life. From helping us prepare our favorite meals to heating our homes during winters, and even driving industrial operations, LPG gas plays an essential role in modern living.

But the story of LPG goes far beyond the flame we see. The journey begins with hydrocarbons that are extracted from crude oil and natural gas. With the help of advanced refining techniques, rigorous purification, and storage processes, this volatile substance is then converted into a clean, reliable, and safe energy source that reaches millions of households and businesses around the world.

In this blog, we’ll be discussing the entire process and you will also be given insights into the technical aspects that ensure its safe and efficient use.

Liquified Petroleum Gas, also known as LPG gas is a flammable hydrocarbon gas that is usually a mixture of propane and butane. It is stored in liquid form under pressure and vaporizes immediately when released. This fuel has a high calorific value, which makes it a widely preferred clean, efficient, and portable fuel source for domestic, commercial, and industrial applications.

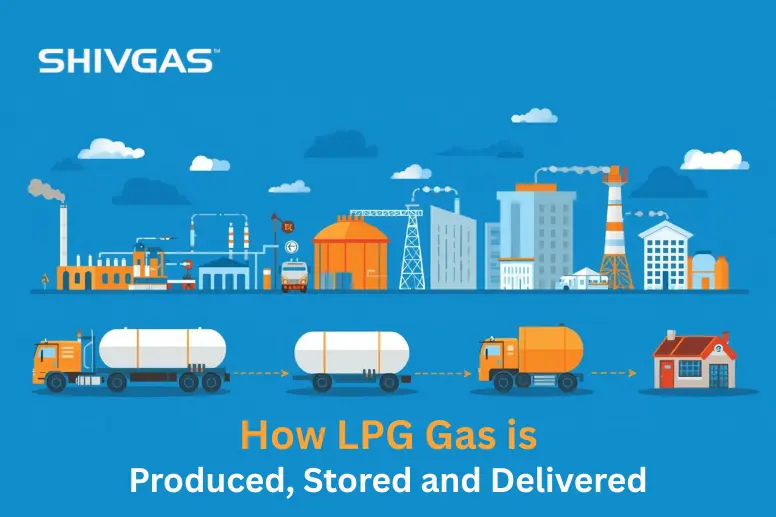

The journey of LPG involves three main stages: it is first produced from natural gas and crude oil, then carefully stored in tanks or cylinders, and finally delivered to homes and businesses safely. Now let us know about each of these processes in detail.

LPG is mainly a byproduct of crude oil refining and natural gas processing. When crude oil is refined, the heavier sediments get separated, leaving behind the lighter gases like propane and butane. Similarly, natural gas plants remove impurities such as water, carbon dioxide, and sulfur to extract pure LPG gas.

A major step in LPG production is fractional distillation. In this process, crude oil is heated in a tall distillation column, where its various components separate according to their boiling points. Lighter hydrocarbons, such as propane and butane, vaporize first. These vapors are then collected, cooled, and compressed into liquid LPG, making it ready for storage and further use.

Before the LPG cylinders reach the end consumers, they undergo a thorough purification process to remove impurities such as moisture, sulfur, and other unwanted substances. After purification, the LPG is subjected to rigorous quality checks to ensure it meets safety and performance standards, including pressure tolerance, energy content, and chemical composition. This makes it safe and reliable for use in homes and businesses.

LPG gas is stored in large tanks at refineries and bottling plants. These tanks are built to handle high pressure and come with safety valves, pressure gauges, and temperature monitors. The tanks can be vertical or horizontal depending on how much LPG they hold.

For domestic use, LPG is stored in steel or composite cylinders. The normal sizes of household LPG cylinders are 14.2 kg, 17 kg, or 21 kg. These cylinders are manufactured according to strict safety standards and undergo regular testing to prevent leaks, corrosion, or damage. Each cylinder has a valve to control the flow of gas to your stove or appliance.

NOTE: Safety is very important when storing LPG. Make sure that the tanks and cylinders have relief valves, flame arrestors, and automatic shut-off systems to prevent accidents. Also keep the LPG cylinders in an area that has proper ventilation to prevent accidents in case of leakage.

Once cylinders are filled and tested, they are transported to distribution centers in special trucks designed to carry flammable liquids. These trucks have safety devices, grounding systems, and emergency shut-off valves to prevent accidents during transportation.

From the distribution center, the LPG cylinders are then delivered to homes and businesses. At the time of delivery, the assigned delivery personnel follows strict safety rules, checks the cylinder condition, verifies the gas connections, and carefully installs it in your facility. Many companies now use real-time digital tracking systems to manage deliveries more efficiently.

In some areas, homes and businesses that depend on LPG, the gas is supplied directly through pipelines. This system uses regulators, pressure controllers, and safety valves. Piped LPG reduces the need for struggling with those heavy cylinders frequently and adds to the convenience.

LPG is more than just a household fuel; it is the result of a carefully managed process that combines advanced technology, strict quality checks, and safety measures at every stage. Refineries produce and purify the gas, while authorized bottling plants fill the cylinders maintaining strict quality standards. After that, reliable LPG suppliers manage the distribution process, where cylinders are safely delivered right at your doorstep.

So, the next time you light your stove, boil water, or use LPG gas for heating, take a moment to think about the journey that brings this essential fuel safely to your facility, making your daily life easier and more convenient.

When your cylinder arrives, check the valve, look for any dents or rust, and make sure that the seal is intact. Reliable suppliers follow strict safety checks before delivery, so a quick inspection gives you extra peace of mind.

Do not attempt to use it. Notify your supplier immediately. They have protocols for damaged cylinders and will replace it immediately.

Household cylinders come in different sizes (like 14.2 kg, 17 kg, or 21 kg) to match consumption patterns. They are filled under controlled conditions at bottling plants and stored safely until delivery.

After filling and testing at bottling plants, LPG cylinders are sent to distribution centers. Advanced tracking systems monitor cylinder stock, deliveries, and refills. This organized system assures that homes and businesses receive cylinders safely and on time, minimizing supply gaps.

In areas with piped LPG systems, regulators, pressure controllers, and safety valves are installed at the source of installation. The gas comes directly from the storage tanks and maintains the same purified quality as you get in normal LPG cylinders.

Comment (0)